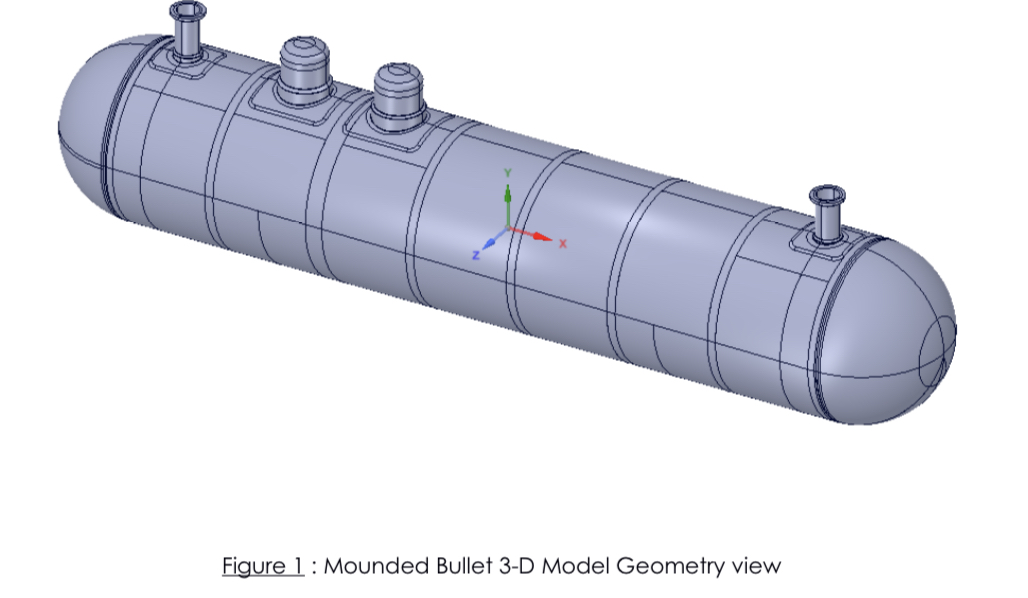

Have you ever wondered how fuels like petrol, diesel, LPG, and even liquid nitrogen, always seem readily available despite their origin from distant locations? The answer lies in mounded bullets—massive pressure vessels strategically placed near city areas to store these high-demand fuels. Imagine structures as tall as a three-story building and stretching up to 100–200 meters long.

Designing, manufacturing, and analyzing these vessels is no small feat. Each one must gain approval from the Petroleum and Safety Organization (PESO), Nagpur, before it can be used. With enormous quantities of flammables, hefty investments, and a critical need for safety, Finite Element Analysis (FEA) becomes indispensable. When analyzing such a structure, the stakes are high—it’s not just about structural integrity but the safety of thousands of lives.

Challenges

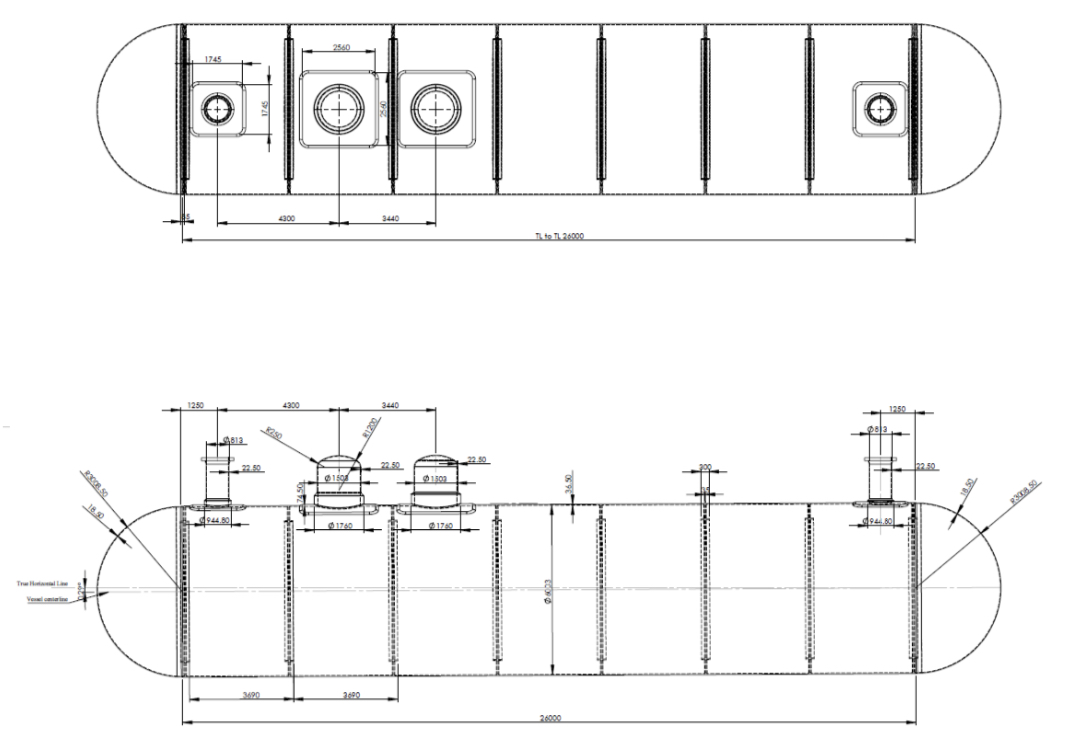

Fig – drafting of mounded bullets.

Mounded bullets are colossal horizontal vessels capable of weighing thousands of tons when filled. Supporting such massive structures presents unique engineering challenges. Traditional designs, requiring upwards of 100 supports, are impractical. Instead, these vessels rest on a mound of compact sand debris, which provides stability while enveloping the vessel above ground.

However, sand debris has its quirks—it settles over time. This introduces stresses caused by the combined weight of the vessel, live loads, seismic activity, and even gas explosions. Every stress, big or small, must be accounted for during an FEA analysis to ensure the vessel’s safety and longevity.

Solution

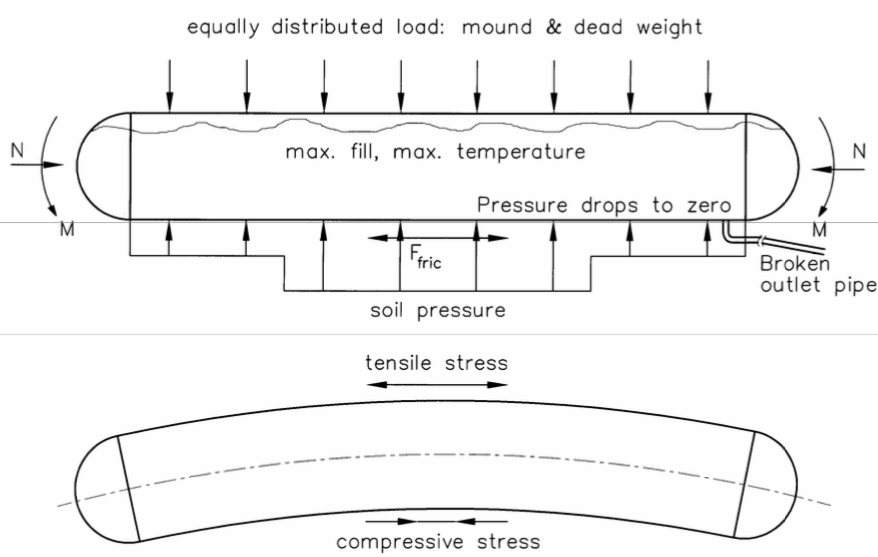

Fig – Representation of End soft case

One of the key challenges with sand debris is settlement, which manifests in two distinct patterns:

- Center Soft Settlement: The middle of the vessel settles more, creating a slight U-shape.

- End Soft Settlement: The ends settle more, bending the vessel into an inverse U-shape.

Critical Load Considerations

The stress analysis of mounded bullets incorporates multiple load factors, including:

- Pressure Load: The internal pressure of the stored fuel.

- Self-Weight: Gravitational pull on the vessel.

- Design Temperature: Ranges from 55°C to -47°C.

- Seismic Load: Forces caused by potential earthquakes.

- Gas Explosion Load: Pressure exerted by the fuel during an explosion.

- Axial Loading: Forces along the vessel’s axis.

- Live Load: 300 kg/m².

- Soil Density: 1800 kg/m³.

- Maximum Allowable Settlement: 50 mm.

12 Load Cases for Analysis

Referring to the Engineering Equipment and Materials Users Association (EEMUA) guidelines, we evaluated 12 specific load cases, each simulating different stress scenarios:

- LC1-LC2: Design pressure + static head + operating weight + mound weight + supporting pressure + seismic load + live load + center/end soft settlement.

- LC3-LC4: Design temperature @ 55°C + all above loads + friction load.

- LC5-LC6: Design temperature @ -47°C + all above loads.

- LC7-LC8: Hydro pressure + static head + test weight (supporting angle 60°/120°) + center/end soft settlement.

- LC9-LC10: Hydro pressure + static head + test weight (120° support angle) + live load.

- LC11-LC12: External pressure + empty weight + mound weight + live load + seismic load.

Results

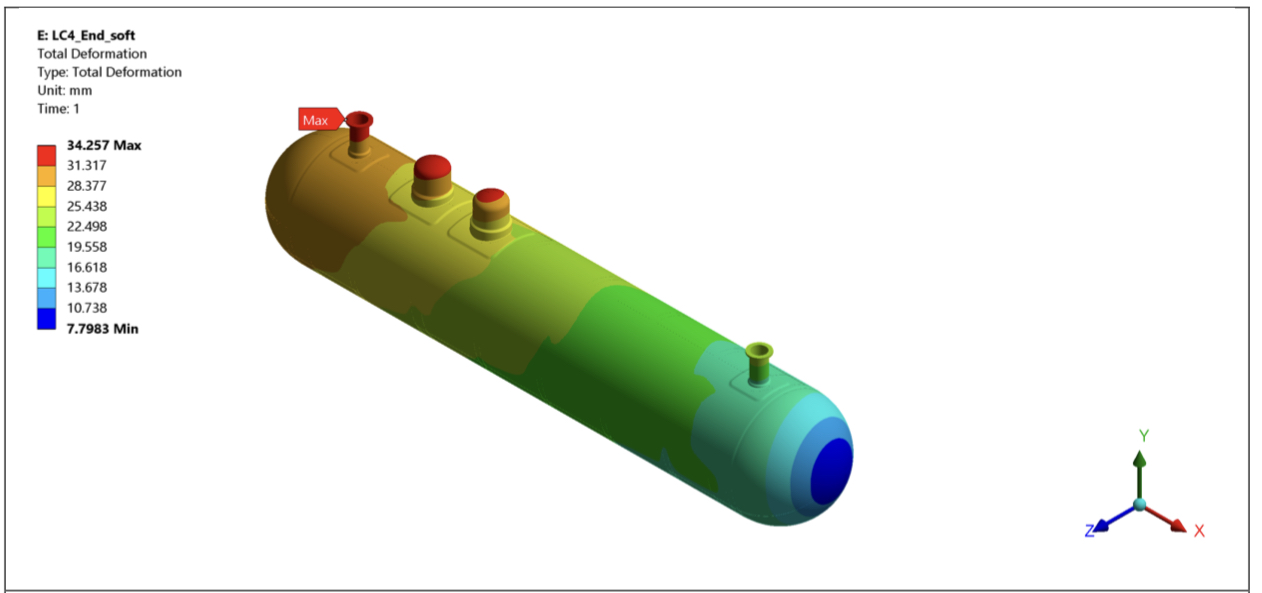

Deformation Analysis

Total deformation was calculated for each load case.

- Maximum Deformation: 34.257 mm, occurring at the left manhole joint in Load Case 4.

Fig – Maximum Deformation

Stress Analysis

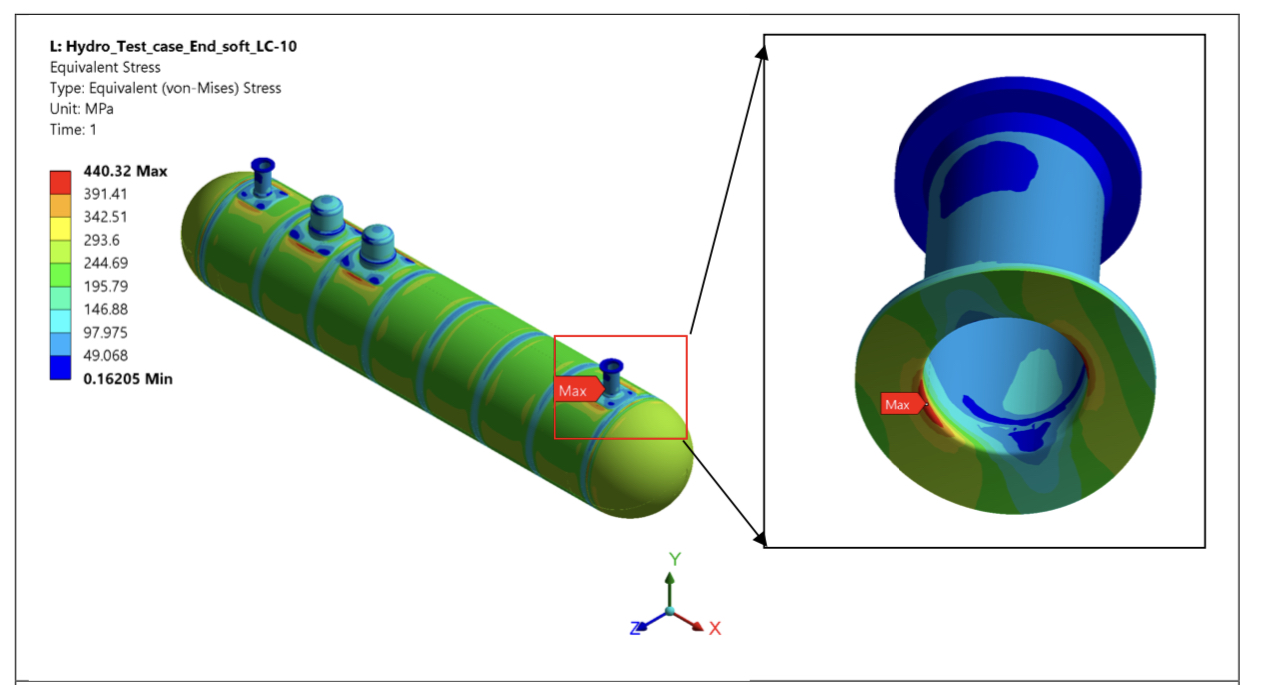

- Maximum Stress: 440.32 MPa, recorded at the right-hand manhole joint in Load Case 10.

Fig – Maximum Stresses.

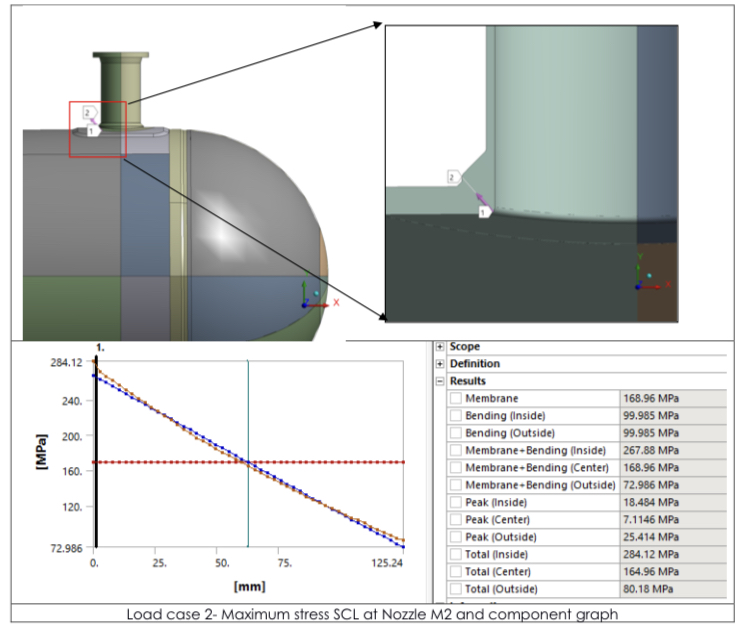

Stress Characterization Line (SCL)

The Stress Characterization Line (SCL) method was employed to evaluate local failures, plotting stress components across the vessel’s thickness. This provided insights into areas prone to high stress concentrations.

Conclusion

The analysis confirmed that the design meets all safety and performance standards:

- Allowable Stress (Primary Local Membrane): 330 MPa.

- Calculated Stresses: 32.041 MPa to 177.68 MPa.

- Combined Stress Limit: 660 MPa.

- Calculated Stresses: 12.025 MPa to 268.11 MPa.

This validation ensured that the mounded bullet design is not only safe but also capable of enduring its operational demands. With these positive results, our client gained the confidence to move forward, knowing their investment was secure and, more importantly, lives would be protected.