When manufacturers design equipment, they must have a clear understanding of its working conditions and the types of loads it will encounter throughout its life. A lack of communication or misalignment in this understanding can lead to premature equipment failure, causing financial and operational setbacks for both the manufacturer and the client. To bridge this gap, Finite Element Analysis (FEA) and fatigue analysis are vital tools. These analyses help calculate the design life cycle of the equipment, taking into account the fluctuating loads it will endure over time.

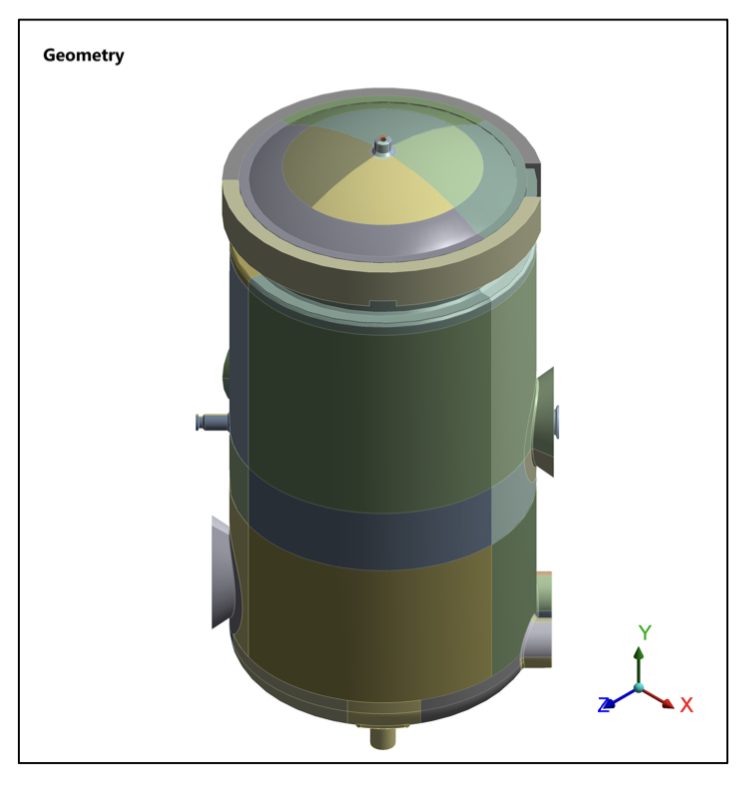

Fig – 3-D view of vertical drum steriliser.

Case Study: Vertical Drum Sterilizer

In September 2021, Pharmalab India Pvt. Ltd. approached us to conduct FEA and fatigue analysis on their vertical drum sterilizer, a key piece of equipment in the pharmaceutical industry. Designed to sterilize instruments, this sterilizer has a maximum capacity of 75 liters.

Challenges

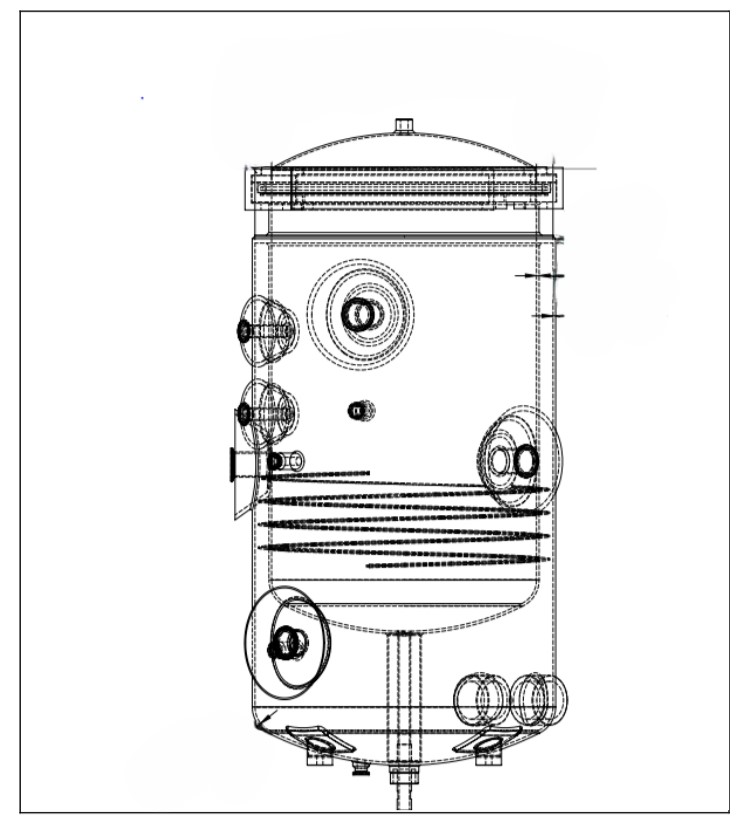

Fig – Full geometry.

The vertical drum sterilizer operates in 90-minute cycles, with the manufacturer quoting a lifespan of 58,400 cycles. Our task was to validate this claim by performing FEA and fatigue analysis to ensure the equipment could handle the quoted lifespan. A critical requirement was that the fatigue damage factor be less than one to confirm the sterilizer’s safety and reliability.

Solution: Understanding Fatigue Analysis

Fatigue analysis assesses how structural components respond to cyclic loads that can cause progressive damage over time. These cyclic loads lead to localized structural weakening, which may result in cracks and, eventually, system failure. Importantly, fatigue damage is cumulative and irreversible.

Design and Function

The vertical drum sterilizer comprises two vessels:

- The Inner Vessel (Shell): Holds the instruments to be sterilized.

- The Outer Vessel (Jacket): Houses the heating system, maintaining a constant temperature and pressure.

During the sterilization process, the shell undergoes fluctuations in pressure and temperature, while the jacket remains steady. This fluctuation makes the shell susceptible to fatigue, as shown in the load histograms below.

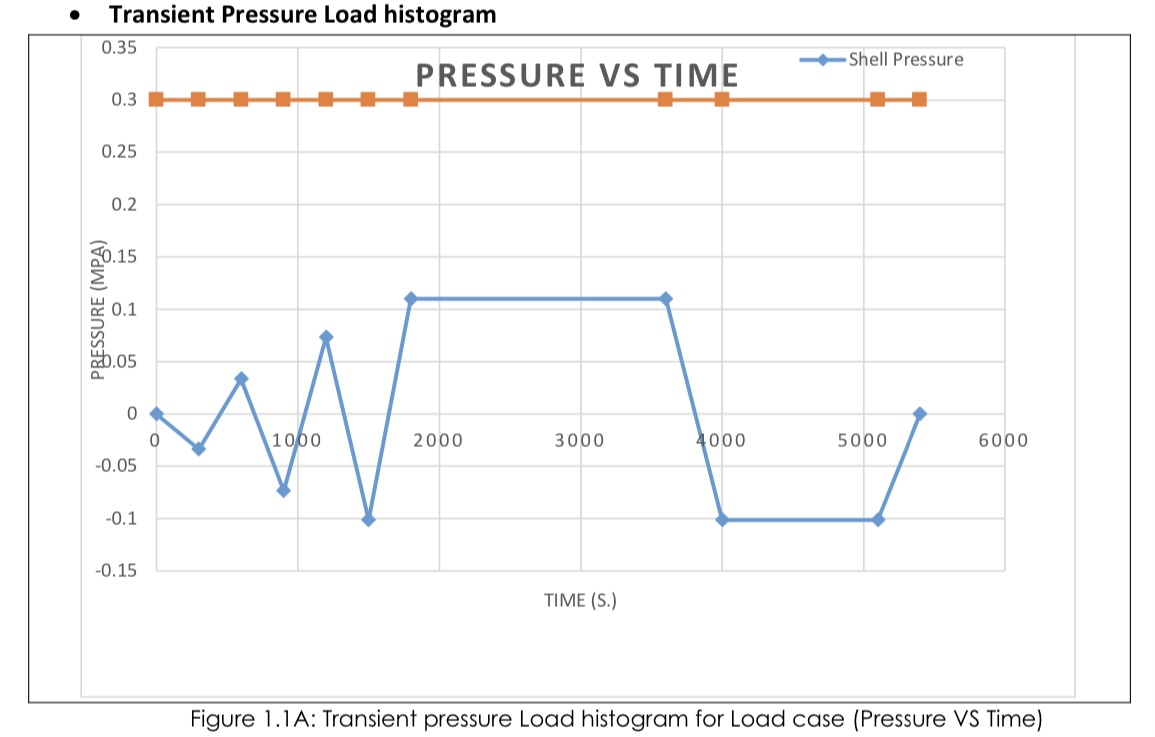

Analyzing Load Fluctuations

- Transient Pressure Histogram

- Jacket Pressure: The orange line remains constant at 0.3 MPa, representing stable heating.

- Shell Pressure: The blue line starts at zero, fluctuates multiple times during sterilization, and stabilizes at 0.11 MPa before returning to zero.

These pressure changes on the shell side create fatigue stress.

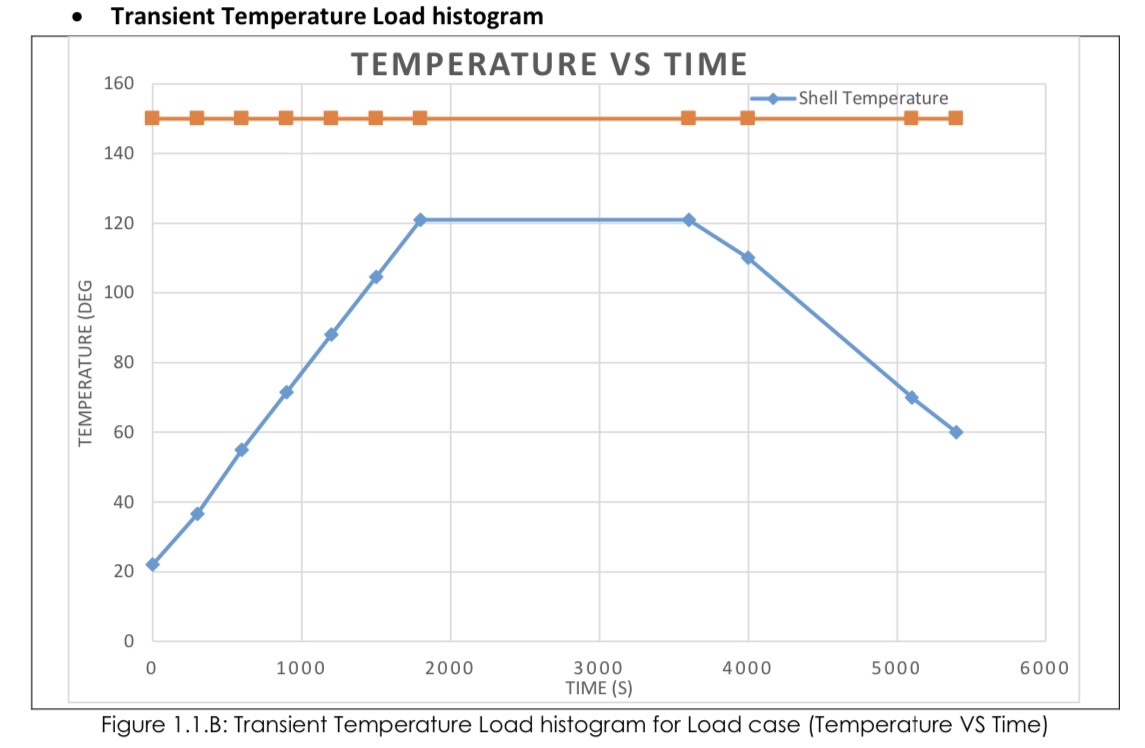

- Transient Temperature Histogram

- Jacket Temperature: The orange line stays consistent at 150°C, indicating constant heating.

- Shell Temperature: The blue line rises gradually to 120°C, holds steady, and then drops to 60°C as the cycle ends.

The temperature variations further contribute to fatigue on the shell side.

Stress Calculations and Fatigue Life

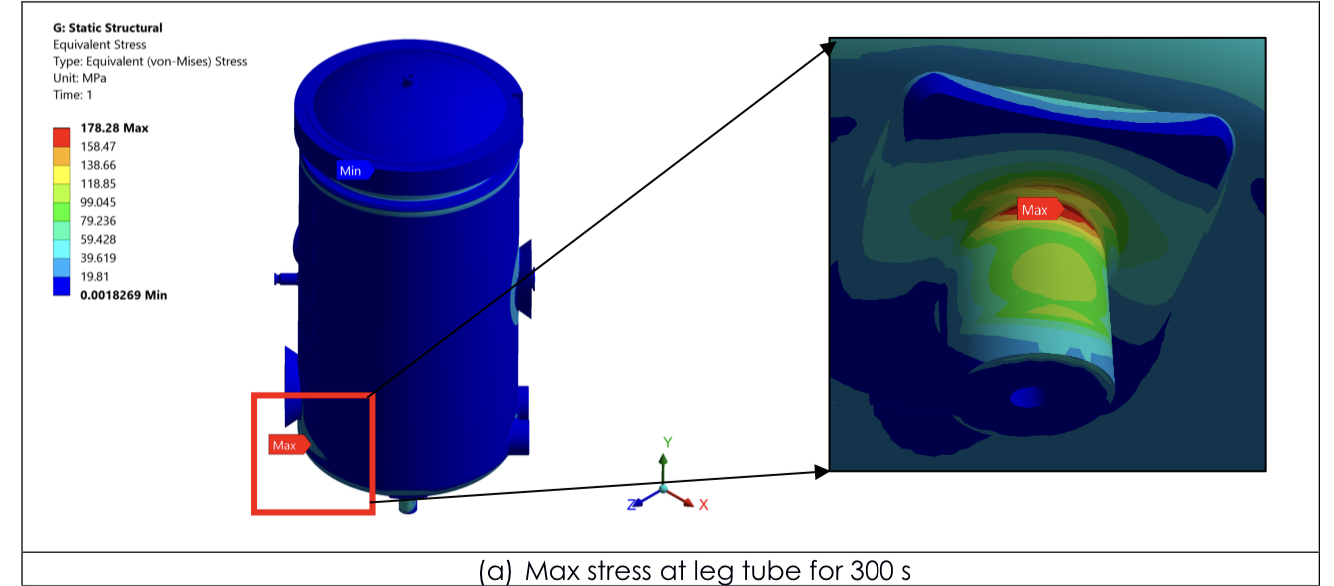

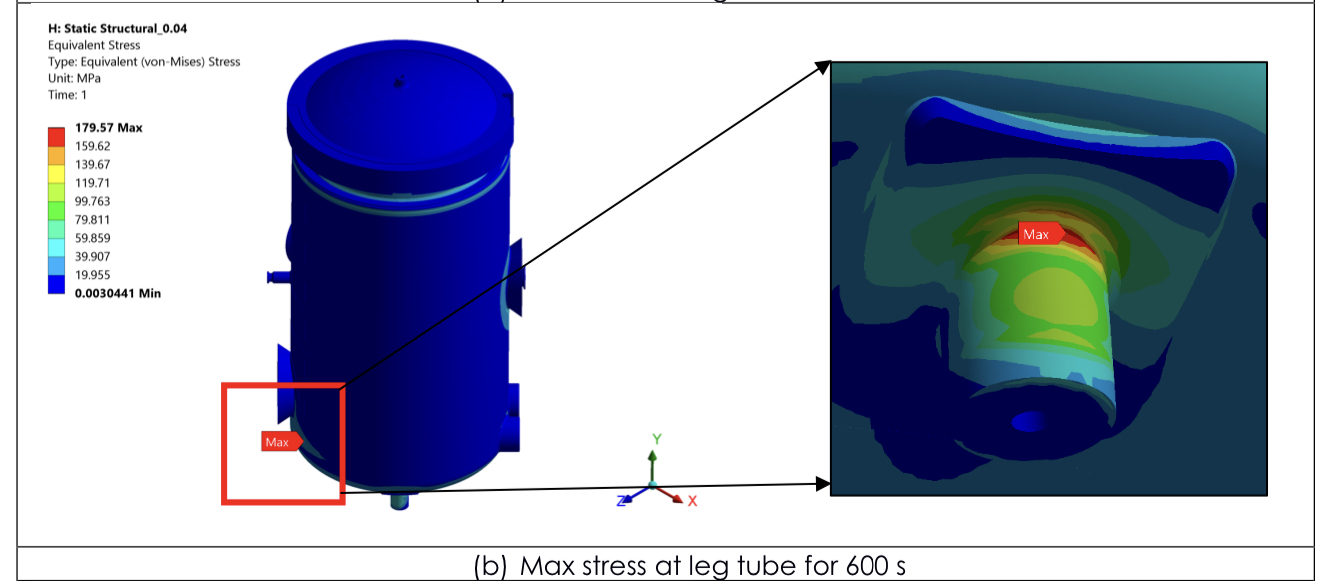

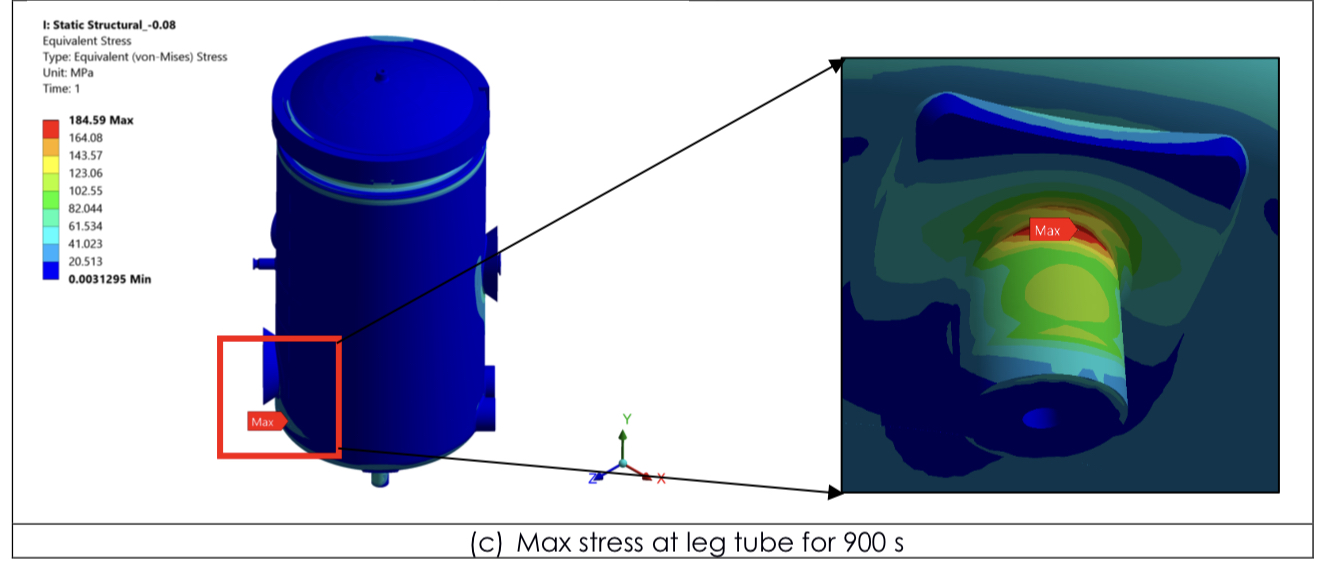

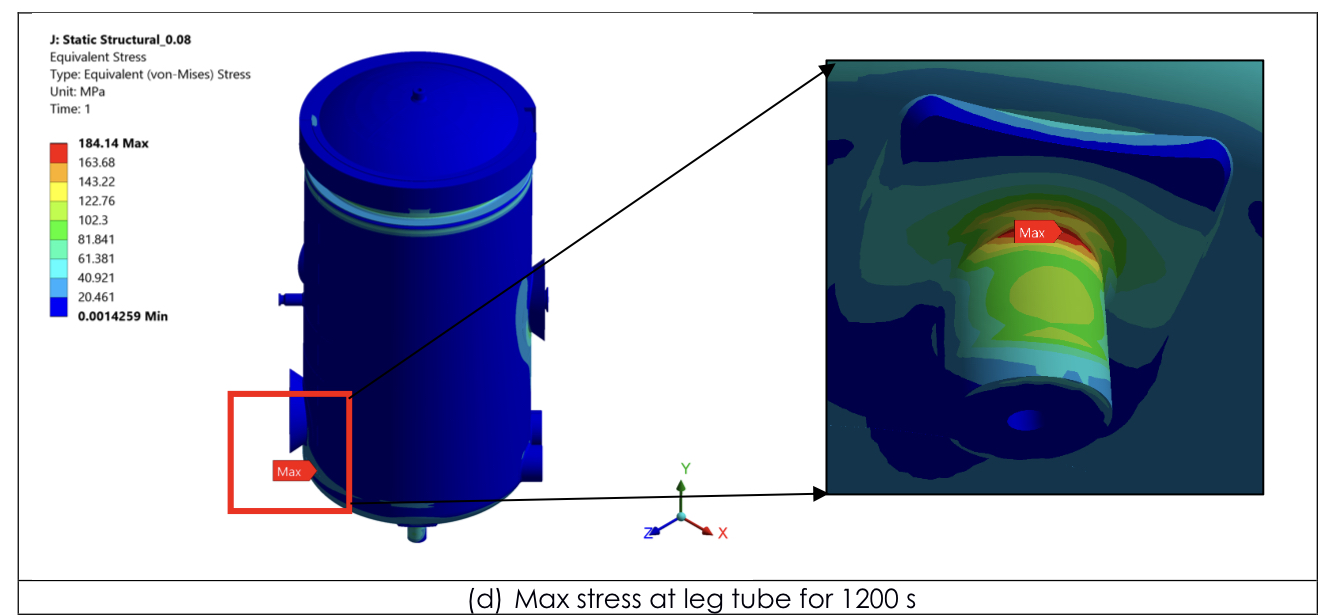

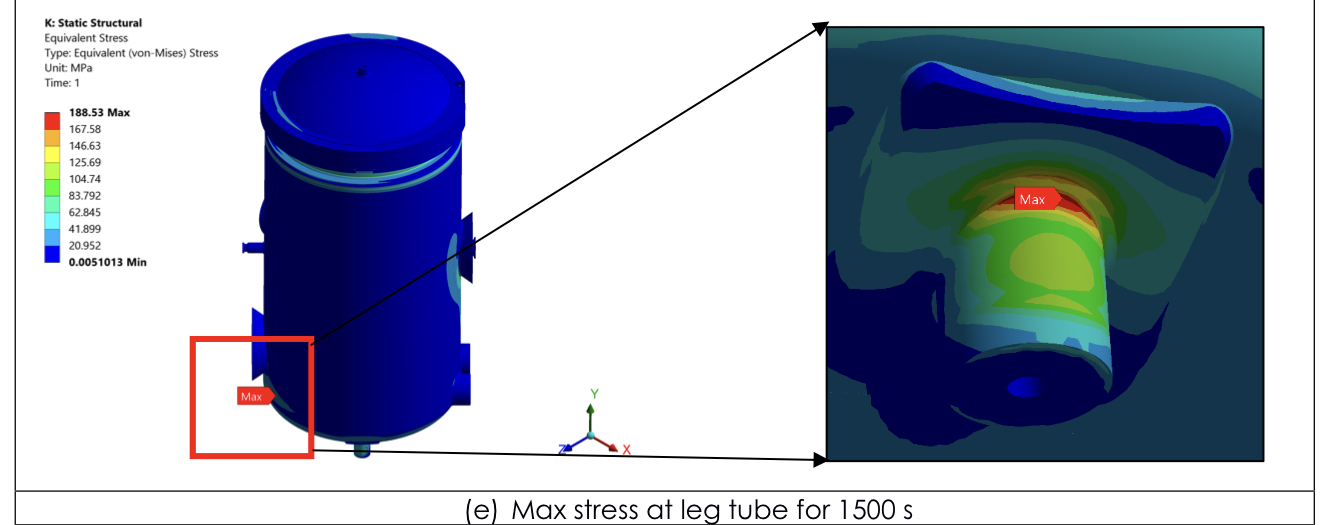

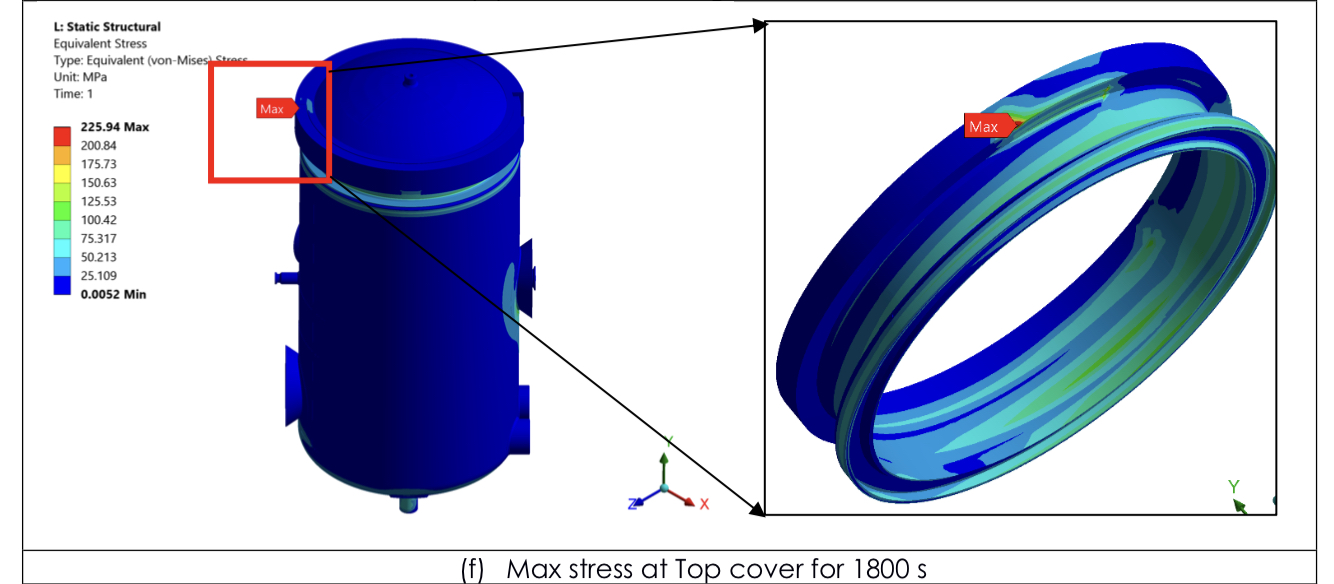

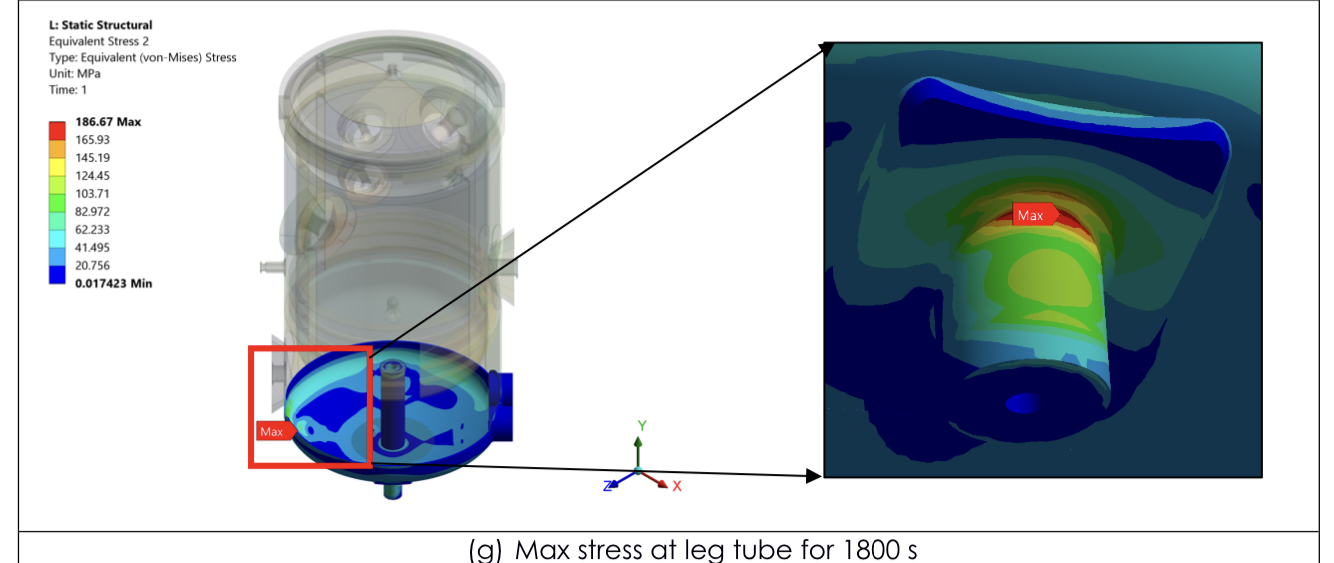

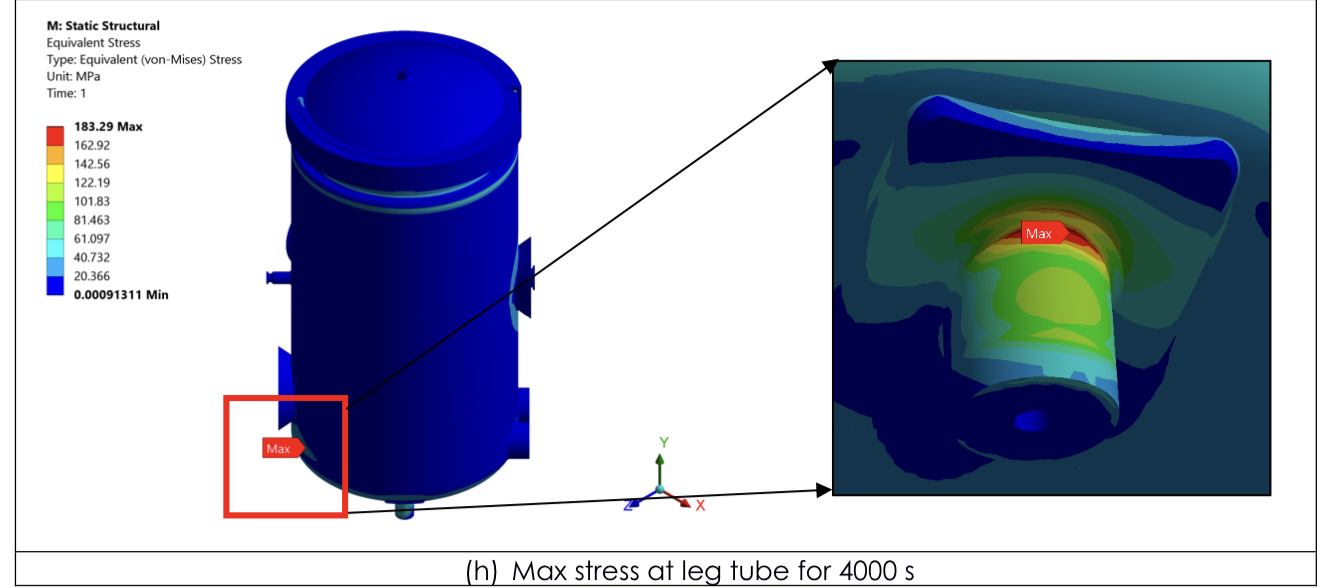

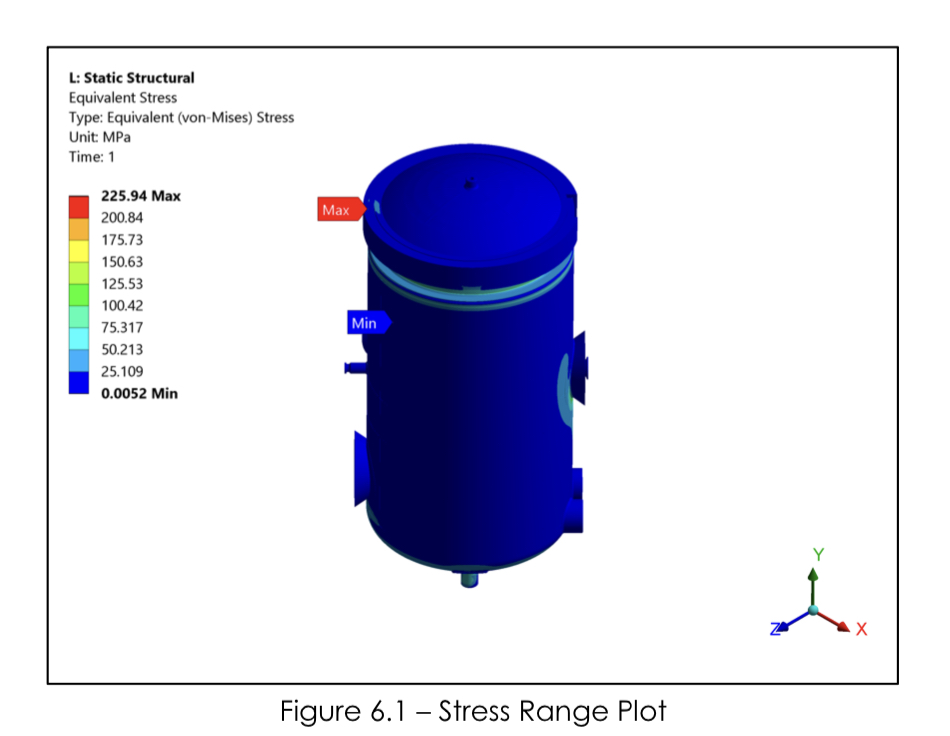

To calculate the sterilizer’s fatigue life, we analyzed stress values at critical points of temperature and pressure change. The images below show stress analysis results (a–f) at each fluctuation instance, revealing a maximum stress of 225.94 MPa.

- Each sterilization cycle takes 90 minutes, resulting in 16 cycles per day.

- Over a 10-year lifespan, the equipment is expected to handle at least 58,400 cycles.

According to ASME Section VIII, Division 2, Part 5, Point 5.5.3.2, the calculated design life for the sterilizer is 1,095,067 cycles—far exceeding the required lifespan. Additionally, the fatigue damage factor for both cyclic pressure and cyclic temperature was found to be less than one, confirming that the design is safe and reliable.

Conclusion

Through FEA and fatigue analysis, we validated the designed lifespan of the vertical drum sterilizer, confirming its ability to withstand the fluctuating loads of the sterilization process. This analysis gave Pharmalab India Pvt. Ltd. the confidence to deliver the equipment to their client, knowing it will operate safely and reliably for years to come.