Creep Analysis

Our API 579 Level 3 Creep Analysis delivers precise insights, ensuring long-term equipment reliability and performance.

Offerings

Main Menu

Offerings

Main Menu

Creep Analysis as per API 579-1/ASME FFS-1

Our Creep Analysis services follow API 579-1/ASME FFS-1 standards to evaluate the long-term integrity of high-temperature equipment. We utilize advanced modeling techniques, including a proprietary in-house subroutine developed specifically to

integrate the MPC OMEGA method with our Finite Element Analysis (FEA) software. This approach enables highly accurate predictions of creep behavior, helping extend equipment lifespan and optimize maintenance strategies.

Step-by-Step Process for Creep Analysis

Characterization of Creep Damage

- Understanding Material Creep Behavior:

- Evaluating the creep properties of materials, such as strain rates and stress rupture data, under high temperatures and sustained loads.

- Collecting data on operational history, including temperature profiles, stress levels, and exposure times.

- Component Assessment:

- Reviewing original design specifications and analyzing historical operating conditions to determine how long the equipment has been exposed to creep-inducing environments.

Finite Element Analysis (FEA) with Proprietary MPC OMEGA Subroutine Integration

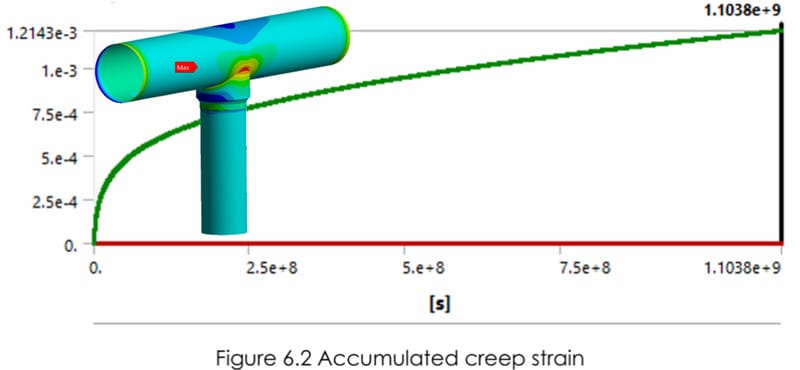

- Simulation of Creep Deformation:

- Using FEA to model the component’s behavior under sustained high-temperature conditions and simulate the redistribution of stress over time.

- In-House Developed Subroutine with MPC OMEGA Method:

- Our proprietary subroutine integrates the MPC OMEGA method into the analysis, providing precise calculations of time-dependent creep strain.

- The subroutine allows for the evaluation of material damage based on the accumulation of creep strain, considering various factors like temperature, stress history, and load duration.

- Enhanced Accuracy in Predictions:

- The in-house subroutine accounts for nonlinear material behavior and stress relaxation effects, leading to more accurate life predictions and better-informed maintenance decisions.

Time-Dependent Stress Analysis

- Creep Rupture Life Estimation:

- Predicting the time to failure based on stress rupture data, using the enhanced accuracy provided by the MPC OMEGA method.

- Damage Accumulation Analysis: Quantifying the extent of damage using time-dependent creep strain data and evaluating how it affects the component’s remaining life.

- Stress Redistribution and Relaxation:

- Simulating changes in stress concentration as creep deformation occurs, which helps in identifying critical areas prone to failure.

Creep-Fatigue Interaction Assessment

- Combining Creep and Fatigue Effects:

- Evaluating how cyclic loading in combination with high

temperatures accelerates material degradation. - Using the subroutine to model complex loading conditions,

incorporating the effects of both time-dependent creep deformation and cyclic fatigue.

- Evaluating how cyclic loading in combination with high

- Failure Mode Predictions:

- Assessing potential failure modes such as crack initiation and propagation due to combined creep and fatigue damage.

Fitness-for-Service Evaluation for Creep-Damaged Equipment

- Determining Suitability for Continued Operation:

- Assessing whether the component can continue to operate safely based on the results of the creep analysis.

- Repair and Life Extension Recommendations:

- Suggesting options like thermal treatments to alleviate creep damage or mechanical interventions to reduce stress

concentrations.

- Suggesting options like thermal treatments to alleviate creep damage or mechanical interventions to reduce stress

- Compliance and Documentation:

- Following API 579-1/ASME FFS-1 guidelines for creep assessment to ensure compliance.

- Providing a detailed report with analysis outcomes, incorporating data from the MPC OMEGA subroutine, and making maintenance recommendations.

Why Choose Us for Creep Analysis?

- Expert Knowledge and Accuracy: Our team is proficient in advanced creep analysis methods and equipped with cutting-edge tools to provide accurate and reliable results.

Compliance with API Standards: We adhere to API 579 Level 3 guidelines, ensuring our analyses meet the highest standards for safety and precision.

- Customized Solutions: We offer tailored analysis to address your specific equipment and operational conditions, delivering practical solutions for long-term performance